by Don Bray

Torque Correspondent

Part Two of Two about Jeep Suspensions and components.

Incorporating a suspension lift on your Jeep is one of the first things many do when they start modifying their vehicles.

And why not.

After all, a lift provides extra ground clearance, the ability to better traverse off-road terrain, creates room for larger tires, adds stronger components to the suspension and just simply makes the Jeep seem more rugged.

In part one of this series, we looked at whether adding a Jeep suspension lift is something that made sense for you. Once that decision is set, the next step comes into play.

Research.

At the onset, this can seem like a daunting task because not only are there a lot of lifts out there, but most lift companies offer many different component options.

For example, Rubicon Express offers a standard type lift kit that contains new coil springs, bump stops, end links, track bar bracket and hardware. However, you can build onto that lift by purchasing components such as control arms, track bars, geometry correction brackets, upgraded shocks and different spring variations.

As we go along, I will address these options, explain what they are and hopefully build your understanding of the pros and cons of each product. The idea is to give you the knowledge to make informed decisions.

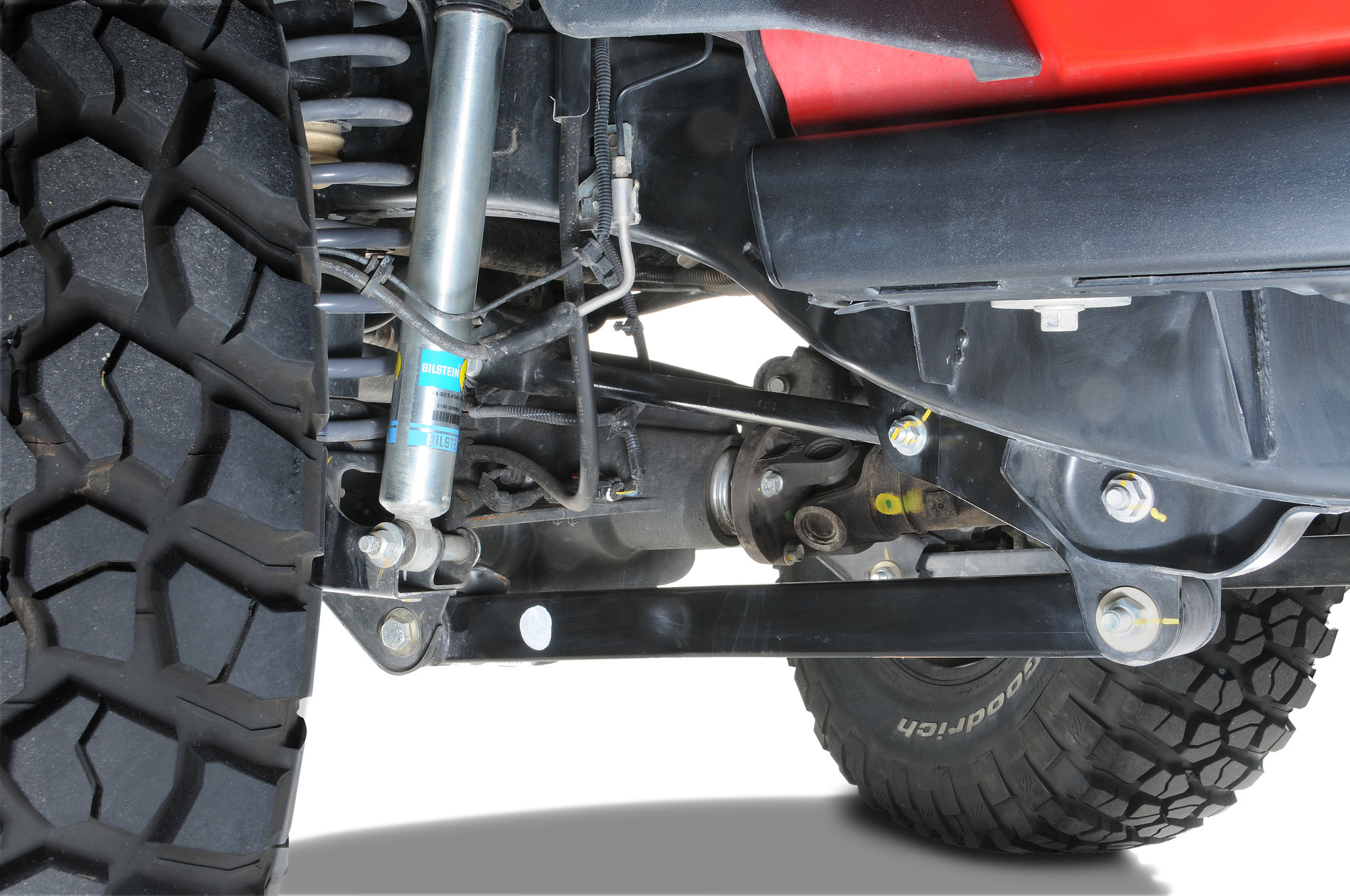

First, let’s look at geometry correction brackets. As the name applies, they do just that — correct all the suspension geometry of the front suspension.

Suspension geometry can be quite complex, as there are angles that need to be within a certain specification or it will affect handling and tire wear. So, geometry brackets will correct both caster and the angle of the control arms. Caster is the difference in degrees when you draw a vertical line through the tire and another through both ball joints. It is also responsible for how well the vehicle tracks and returns the steering wheel to center.

Geometry correction brackets bolt to existing factory brackets, moving both the upper and lower control arms forward. This corrects the caster and brings it more in line with factory specifications.

The other unique feature about geometry correction brackets, they will correct control arm geometry. Control arms need to be perpendicular to the road as this helps control how the axle is loaded when you brake and accelerate.

Geometry correction brackets overall are very cost-effective and work well to keep your ride quality closer to factory after adding a lift. The only real issue with these brackets is the way they sit after attaching to the factory versions. This attachment seats the aftermarket brackets lower, so they can be prone to hanging up on rocks in more difficult off-road environments.

Another component options is to replace the control arms.

Control arms serve to regulate the up and down movement of the axle. On a Jeep, there are four for each axle — an upper and lower control arm on each side.

Now, most suspension companies make control arms to complement their suspension systems so first I’ll talk about adjustable versus non-adjustable.

The benefit to having adjustable control arms is to allow adjustment for caster. By lengthening or shorting either the upper or lower control arms, you can bring your caster measurement back within specification as the lift kit is installed.

These days, different suspension companies use different variations, but I’ve found most offer both fixed and adjustable upper and lower control arm options in their kits. In my personal experience, I like to use adjustable upper control arms and fixed lower. This simply keeps the adjustable control arm up off the rocks and the jam nut away from damage. However, this may vary depending on your application.

Something else to consider when looking at control arms; long versus short.

Long arms, as the name applies, means that the actual component length is longer. This, in turn, will increase the radius of the control arm. In laymen’s terms, it means increased suspension travel and overall geometry closer to factory. However, the only way to ensure proper geometry, and the best ride quality, is to use control arm drop brackets.

The last thing to understand when choosing control arms is the type of joint the product uses as there are three basic types of joints — heim, some variation of rubber and hybrid joints.

Stock Wrangler control arms are equipped with a rubber joint, and they are vulcanized to the inside of the sleeve and to the eyelet. This works great to help isolate the vehicle from road vibrations, however it does create binding when the suspension is near its max travel limits, thus limiting articulation.

A heim joint is a mechanical joint that uses a “ball and socket” type design. Heim joints tend to allow for more articulation, but transmit more vibration from the road to the driver. Another plus is that heim joints are rebuildable should they become damaged somewhere in their lifespan.

Finally, there is a hybrid joint called “Johnny Joint” which is proprietary to Currie Enterprises. This hybrid edition uses a heim joint design, but the ball is encased in urethane which created a smoother ride with much less road vibration.

Whatever direction you decide when choosing control arms for your Jeep’s lift kit, make sure to understand exactly what they come with because, as I mentioned, all of these options have their own pros and cons.

Next, we will look at track bars.

A Jeep track bar centers the axle to the body and runs from one corner of the axle to the opposite side of the body. Inevitably, you will need to either replace it or add a bracket, because as you lift the frame away from the axle, the distance between the two increases.

So, option one is to add a bracket to either the axle or body where the track bar connects. This is the most common option with lower-price lifts. However, I typically look for a body-mounted bracket as this helps to lower the roll center of the vehicle.

The second option is to replace the factory track bar with a longer aftermarket version. In most cases these types of track bars are adjustable which definitely helps drivability when adding that new lift kit.

Either way, it is important to utilize one of these two options when adding a lift kit because proper track bar length allows the vehicle to track better on the road. Incorrect track bar length can present a dangerous driving condition — causing the vehicle to need constant correction from the driver and making the Jeep constantly feel like it is swaying.

Moving on to Jeep springs.

This is one of the biggest decisions that needs to be made when you choose a lift kit, as they are a huge part of the suspension system and key in determining ride feel, ride quality, suspension travel and handling.

There are three different types of springs to understand, and the first is a linear spring. This one provides the same spring rate throughout its cycle and is great for setting ride height and providing consistent performance. The downside to a linear spring is the ride quality tends to be slightly more stiff than what you had with the factory springs.

The second spring choice is a progressive rate coil. This type of spring coil changes its spring rate as it becomes more compressed, thus providing better ride quality. However, the drawback is that it’s not as durable as a linear spring.

You’ll find both linear and progressive rate springs in many entry-level type lift kits.

The third spring on the market is called multi-rate. These coils are similar to progressive rate springs except that the upper coil is a different rate than the lower one. Essentially, this means the upper portion of the coil operates at a total different rate and independent of the lower coil, thus providing far better off-road performance and ride quality. Again, though, the drawback to this is durability and spring fatigue over time.

These springs are generally typical in mid-to upper-level lift kits.

Finally, we can talk about shocks and these days there are many different available options that can enhance ride quality for both on- and off-road use.

Like coils springs, shocks play an extremely important role in how your Jeep handles and performs. First, let me state a disclaimer. Unless you are a suspension specialist, look to use the recommended shock that matches the your coil type.

That’s because different shocks have different valving. In other words, shocks typically are tuned for specific coils or situations, and they are matched for the maximum suspension travel designed into the lift. So every shock has a maximum extended and minimum compressed length that needs to be matched to the coil.

That being said, you have many different options and most companies will automatically give you suggestions to match the lift you are choosing.

Using Rubicon Express' 3.5-inch sport suspension system as an example; there are three different shock options — monotube, twin-tube, and adjustable. In this case, the twin-tube shock is the cheaper option. The monotube would be the second-best shock as compared to the adjustable being the best.

The difference between the monotube and twin-tube shock is the construction. The twin-tube has multiple valves and reacts slower to changes in terrain, while the mono-tube shock has only one valve that is able to adjust more quickly.

Generally, the differences in shocks can be either through construction, oil volume, tuning or dampening material. So to sum up what shock is right for you; typically, you want to look for a monotube style shock. Additionally, the larger the oil capacity the better for you.

And finally, if you can afford it, adjustable shocks will give you the best of both and ability to adjust your ride quality based on conditions.

As I said earlier, there are tons of choices when choosing a new suspension lift for your Jeep. However, if you don’t choose wisely, or rush the process, you will most likely end up with a Jeep that isn’t fun to drive. Sure, it may look nice, but it won’t perform the way you want.

Making good, informed decisions will save you money in the long run and certainly increase the amount of enjoyment you get from your Jeep.

Remember, change what you can, accept what you can’t, and be smart enough to know the difference.

Top Jeep Articles

- May 16, 2024

- 5 min read

- May 14, 2024

- 5 min read

- May 10, 2024

- 15 min read

- May 8, 2024

- 10 min read

- May 6, 2024

- May 2, 2024

- 5 min read

- April 26, 2024

- 10 min read