A Brief history of the Internal Combustion Engine (ICE)

In 1860, the very first gas-fueled Internal Combustion Engine was created by Jean Joseph Etienne Lenoir. This was the first type of ICE to be produced in numbers. In 1861, the first style of a 4-stroke engine was made and patented but it wasn't until 1876 that the engine became an in-cylinder compression design. By 1884, British engineer Edward Butler created the first gasoline (petrol) internal combustion 4 stroke engine. Edward Butler is also responsible for the inventions of spark plugs, coil ignitions, magnetos, and spray-jet carburetor systems.

The 4 Stroke Engine Process

The 4 stroke internal combustion engine has four individual steps, as the name implies. These strokes are the intake, compression, power, and exhaust strokes. These strokes repeat every 2 revolutions of the engine.

Step 1

Intake Stroke This is the start of the combustion process, also known as a suction stroke, air and vaporized fuel are drawn into the cylinder by way of vacuum pressure. The piston starts at the top of the cylinder camber, known as Top Dead Center (TDC). At this time the intake port opens, and the piston moves downward towards Bottom Dead Center (BDC) drawing in the vaporized air-fuel mixture. The intake valve closes at the end of this stroke.

Step 2

Compression Stroke Once the piston reaches BDC, both intake and exhaust valves are closed, and it will start to move towards TDC again. During this movement, the air-fuel mixture becomes compressed and pressure, tempurature and fuel mixture density are increased.

Step 3

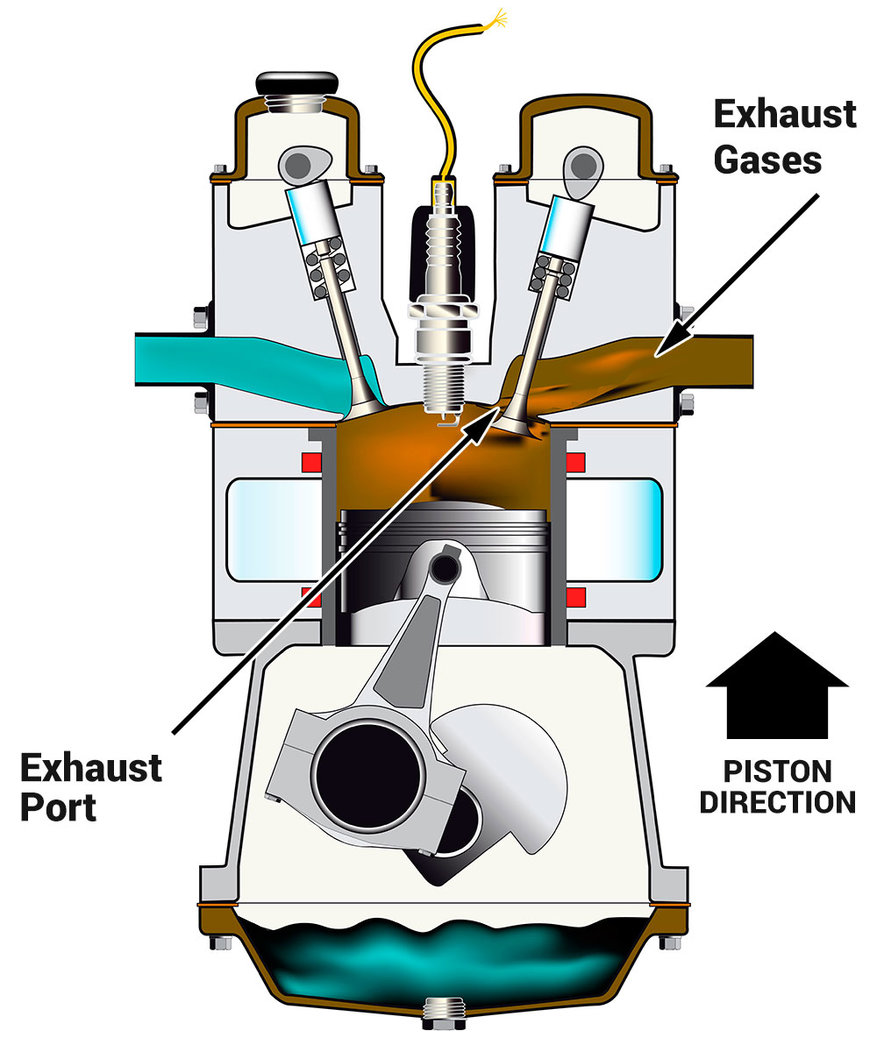

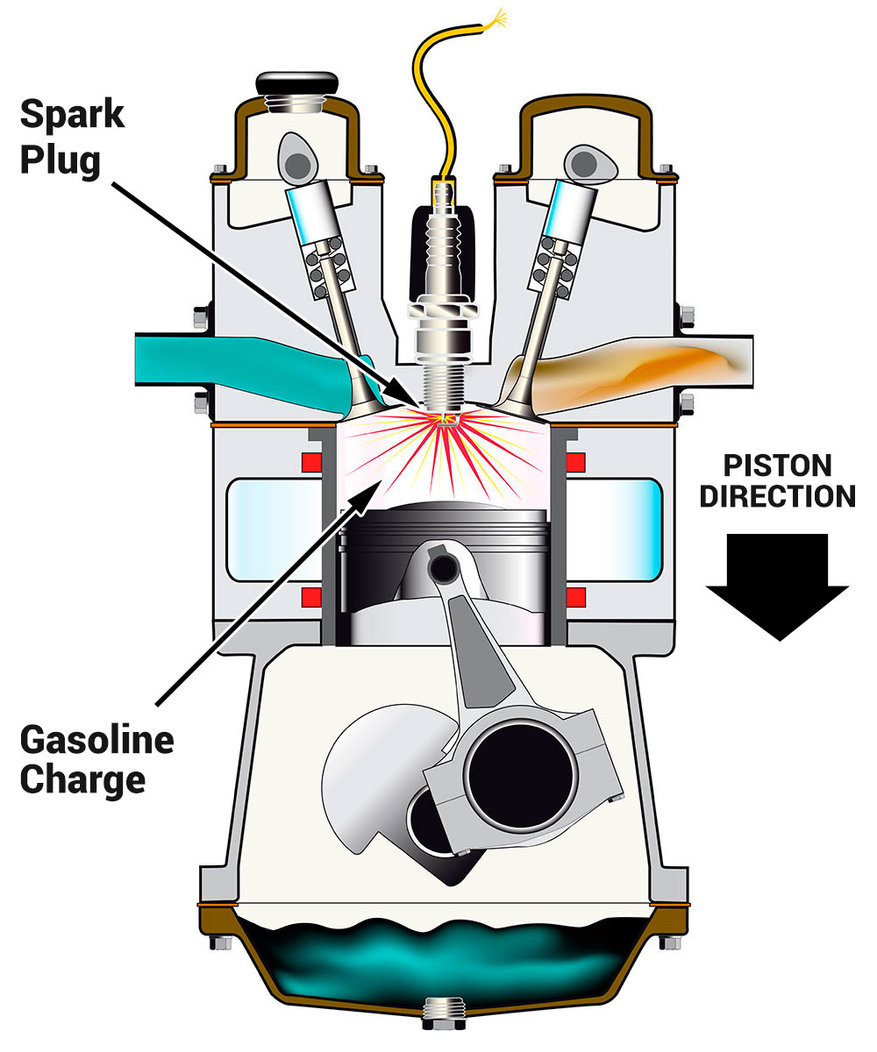

Power Stroke Generally, several degrees in timing before the piston reaches TDC, (also known as Before Top Dead Center or BTDC), the ignition system sparks the spark plug. This creates a burn wave through out the compressed air-fuel mixture. The expansion of this mixture drives the piston down, thus creating the physical force of useful power that is transferred into the crankshaft.